By Lindsey Doermann

August 6, 2019

An award-winning senior capstone design team has a simple formula for generating medical oxygen in remote or underserved areas

As we live and breathe, oxygen is easy to take for granted. The life-sustaining element surrounds us. What’s more, when the need arises, it’s readily available in medical facilities in the Western world. But for a child with pneumonia in Ethiopia or lung disease patient in an area struck by natural disaster, getting oxygen isn’t trivial.

It’s this seemingly-simple problem that ChemE undergraduates took on this past year in a sequence of special design courses. A team of seniors Sophia Nguyen, Harrison Sarsito, and Annalisa Ursino, and junior Gabe Lozada, developed a portable, solar-powered oxygen concentrator for use in regions that are remote and/or lack reliable electricity. They also collaborated with a UW MBA student to develop a business plan for their product, which they call ElectroSolar Oxygen.

The ElectroSolar Oxygen team (L to R: Ursino, Nguyen, Sarsito, Lozada) works on its prototype in the lab. Photo: Dennis Wise/University of Washington

The team’s year of researching and refining, tinkering and rethinking, paid off. ElectroSolar Oxygen brought home the $5,000 Clean Energy Prize at the UW Foster School’s Environmental Innovation Challenge, and the $5,000 Social Impact Prize at the Dempsey Startup Competition. In addition, the ChemE department selected the team to receive the Ray & Priscilla Bowen Award for Process Design, which it presents each year to an outstanding capstone design team.

The Special Design Program that spawned ElectroSolar Oxygen has become a mainstay in the ChemE curriculum for students who want experience not only with chemical product design but also with tech-based entrepreneurship. The three-course option launched in 2012 as the brainchild of professor Dan Schwartz. Professor Lilo Pozzo leads the design program as both course instructor and adviser on entrepreneurship.

Each year Pozzo selects a different theme for students to develop their technology around. For example, in 2015-16, it was food technology. That year’s team designed pouches containing a material that selectively extracts caffeine from brewed cups of coffee. They went on to launch the company Decafino to produce and sell their product.

This year, Pozzo tasked the students with devising a technology to address one of the UN’s Sustainable Development Goals. After considering a range of product ideas, Pozzo helped the ElectroSolar team focus in on oxygen concentration — an idea that stemmed from her work on public health and sustainable energy in the aftermath of Hurricane Maria in Puerto Rico.

And with that, the group took a deep breath — and drilled down into the problem of providing reliable medical oxygen sources in developing countries, rural areas, and disaster-stricken regions.

Current options for supplemental oxygen don’t work well in those cases. Oxygen tanks either have to be routinely transported to medical facilities and trucked out when empty; or facilities can use on-site concentrators called pressure swing absorption (PSA) systems, which require maintenance, a reliable electricity source, and a whole lot of energy.

The team wondered if they could design a system that produced oxygen on location, using only renewable energy sources. And it turns out they could, with a creative use of good old electrolysis. The ElectroSolar Oxygen cell consists of a catalytic membrane sandwiched between an anode and cathode; electric current from a solar panel splits H2O molecules into oxygen gas and hydrogen cations (not volatile hydrogen gas). Similar cells, using the same Nafion membranes that ElectroSolar Oxygen does, are commonly used to produce hydrogen as feedstock for fuel cells. The ChemE team, however, harnessed them to generate medical-grade oxygen gas. Their goal is for each unit to be able to sustain 4–5 patients and fit in the back of a pickup truck.

Getting to this elegant solution, of course, was no simple task. To start, Harrison, Sophia, Annalisa, and Gabe knew they had to beef up their electrochemistry knowledge. They approached professor Stu Adler for guidance. Adler specializes in this area, having worked extensively on oxygen concentration, and he signed on as an adviser to the team.

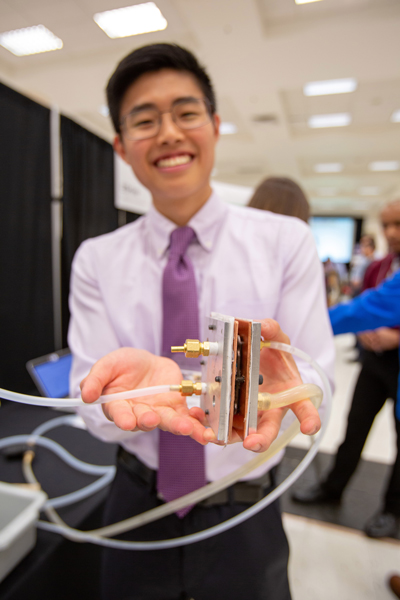

Sarsito holds the prototype electrolyzer cell. Photo ©University of Washington

Initially, they talked about electrolyzing water, and potentially even using the resulting H2 as fuel to power the device. However, the presence of explosive hydrogen gas posed unacceptable safety issues. To circumvent them, they discovered they could use a Nafion membrane to make a cell that was not only safer, but also simpler. The membrane transports H+ ions across the cell where they react with oxygen in the air to form water as a byproduct. The project had a “trial-by-fire element,” said Adler, adding that it was gratifying to see the team come up with a solution that wasn’t immediately intuitive to him.

Each student gravitated toward parts of the project that they could specialize in — and that got the team dynamic really humming. For example, Nguyen worked on COMSOL simulation of fluid flow through the cell; Ursino took the lead on prototyping and testing; Sarsito went deep into the business aspects; and Lozada, the lone junior on the team, worked across multiple elements, gaining a more holistic view so he could continue working on oxygen-concentrator designs as a senior.

To build a functioning device, the students found themselves up against some not-insignificant obstacles. “It's one thing to excel in a classroom, but a different type of challenge to apply that knowledge and build a prototype,” said Ursino. Reconciling the theory of how something should work and actually creating it, said Sarsito, “was challenging but rewarding.” Everyone had to revisit concepts from past coursework and put them into action.

Then there was learning how to use a lot of equipment in order to build something, said Nguyen. Or scouring the plumbing section at Home Depot looking for the right fittings, something Ursino never thought she’d be doing on her way to a ChemE degree.

And that was just on the technical side. Going into the project, said Sarsito, “we didn’t know how to navigate the business side.” But finding that aspect intriguing, he took the initiative to comb through LinkedIn for people with relevant experience, leverage department connections to meet with successful alumni entrepreneurs, and tap into UW CoMotion resources to learn about business development. He also forged a working relationship with MBA student Shobhit Gupta, who helped the team with their pitch and business plan.

Ultimately, the group found the work rewarding — and they were recognized more broadly for their perseverance. As spring rolled around, all three Special Design Program teams were developing prototypes and business models in preparation for several entrepreneurship competitions sponsored by UW’s Foster School of Business. ElectroSolar Oxygen was very much a work in progress throughout, and they went up against projects that had been under development for much longer than theirs.

But they felt that their belief in the technology’s potential helped propel them to success. When they won the Clean Energy Prize, Harrison noted, they wouldn’t run the prototype because water would just leak out. “What helped us,” he said, “is that the end goal of the product is very high-impact.”

By the time they won the Social Impact Prize, the group had really fleshed out a business model, complete with a roadmap to production scale up, target market analysis, potential risks and impact, and projected revenue.

Sarsito, Nguyen, and Lozada after winning the Clean Energy Prize at the Environmental Innovation Challenge. Photo ©University of Washington

“This group was unmatched in the ownership of this project,” said Adler. He said they brought a real passion to the project, and all of the work they did was top quality.

As for what’s next: the group can see a path forward to a provisional patent for ElectroSolar Oxygen, but with most having graduated, newer projects may take precedent. Lozada will continue to work on oxygen concentration as he completes his degree. And with any luck, more people around the world might someday breathe much easier.