Better equipped, more connected, and focused on renewable fuels. The Unit Ops Lab II (ChemE 437) has been restructured and modernized with new equipment and connected experiments. Now with all major modifications implemented, ChemE 437 is a dynamic class that presents students with the real-world challenges of working in a biofuels processing plant.

In 2010, Prof. Pozzo and former lecturer Marvi Matos were awarded a National Science Foundation grant for $200,000 to modernize the Unit Ops II lab. Before the grant and upgrade, the lab’s sets of experiments didn’t bridge well from the junior year’s Unit Ops I (ChemE 436) to the senior year’s Unit Ops II (ChemE 437). With assistance from Prof. Jim Pfaendtner, Pozzo tranformed the lab, adding new and upgrading existing instruments and experiments. With the addition of fermenting and biomass equipment, the disparate experiments now connect, creating a more cohesive laboratory experience for the undergraduate students.

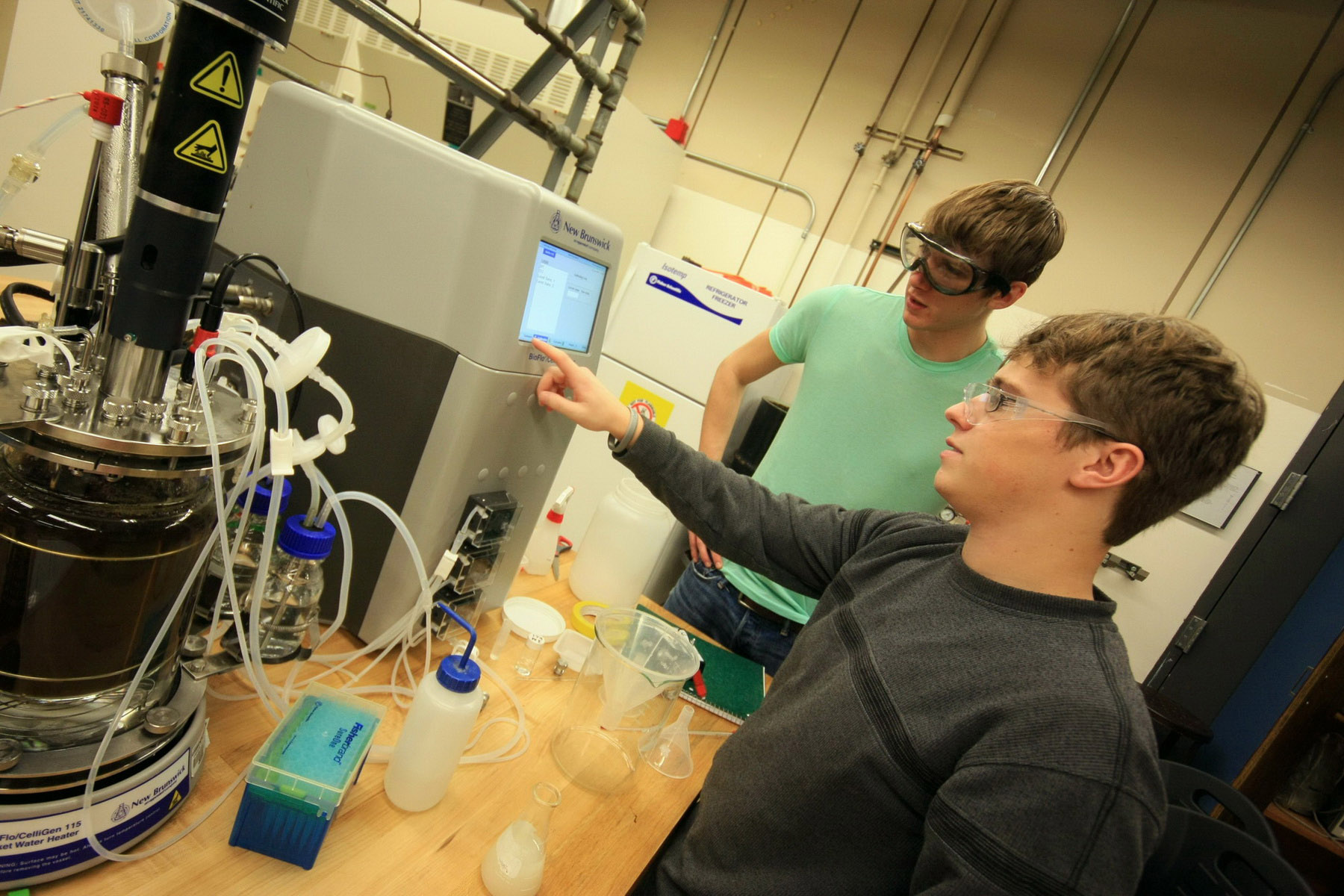

“Through an NSF grant that I lead, we secured funding to unify all of the laboratory experiments of this lab under the theme of bio-fuel processing. This effort resulted in the investment of more than $200K in new equipment (e.g. fermenters, gas chromatographs and HPLC) and the modernization of modules,” said Prof. Pozzo. “The new laboratory now provides students with a more realistic industrial experience where group interactions are encouraged and are also essential to achieving success. Furthermore, students are now able to directly observe how changes to processing parameters in any unit cascade throughout a plant and can have profound and unexpected economic effects.”

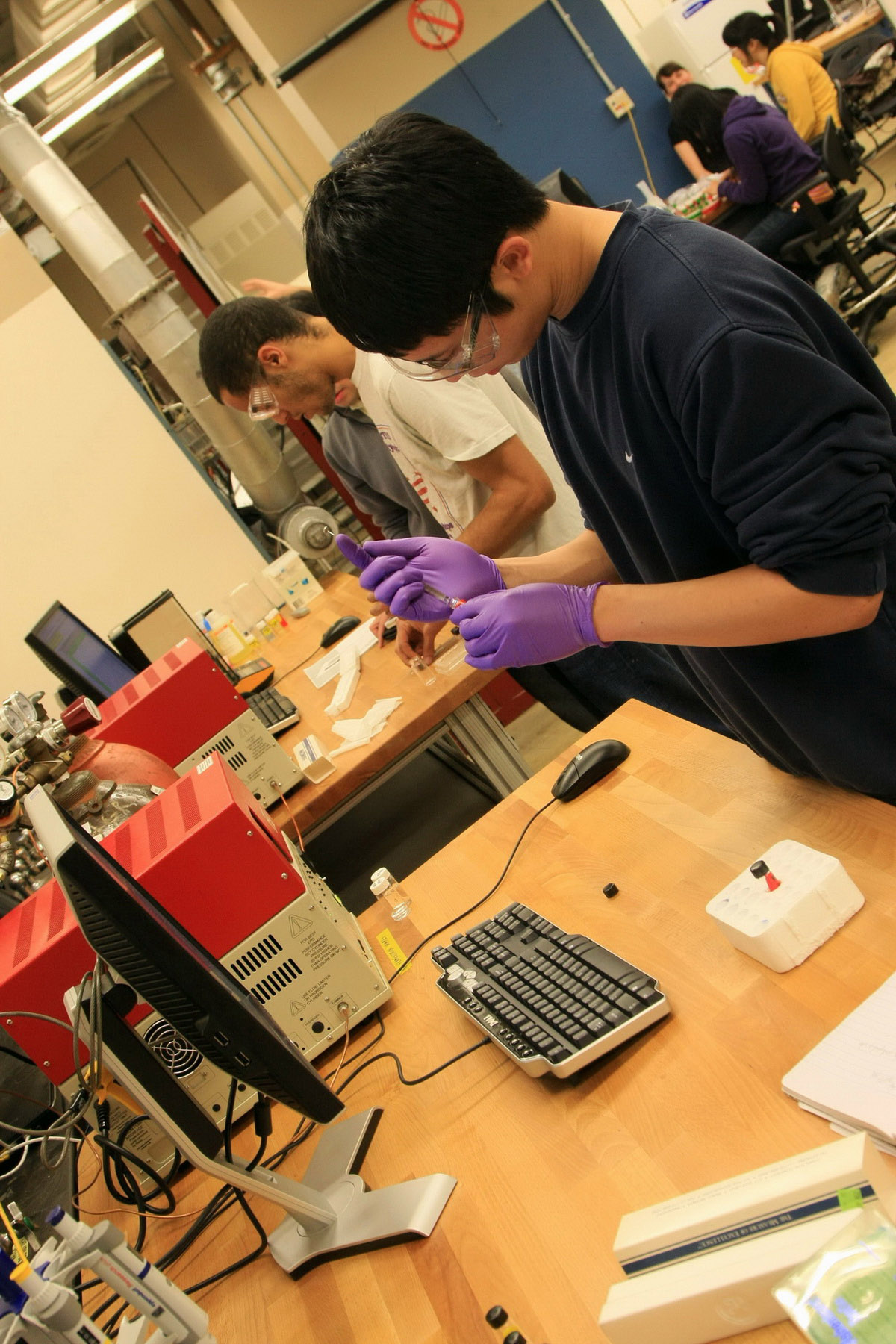

Students in Unit Ops II now work together in small groups at the mock company “Northwest Biofuels.” They learn ChemE fundamentals in mass transportation, heat exchange, concepts for the energy and biotech industries, and undertake industry operations in distillation, absorption, enzymatic reactions and fermentation processes. Through student surveys and external evaluations, Pozzo has been collecting and analyzing data on the upgrades’ effectiveness. “Students have said that the activities are a lot more relevant and they are more excited to perform the labs,” Pozzo said. “But they also say that it is a LOT more work for them.”

Chair Dan Schwartz has applauded Pozzo’s efforts to upgrade the lab, which has benefitted the department, its curriculum, and undergrads. “I am especially excited about the new vision for the lab. By integrating experiments into a full process, students can now see that materials and information both flow through a process. That idea is at the heart of modern automated manufacturing.”

Unit Ops will continue to be improved and streamlined, like the new scrubber experiment being installed this year. “We keep updating the lab as we go. It is a constant work in progress,” said Pozzo.