By Lindsey Doermann

December 10, 2020

Lab experiences help shape a chemical engineer’s education. When COVID-19 forced classes online in the spring, ChemE decided to delay the first unit operations lab course for the Class of 2021 cohort until fall. There was hope that it could be held in person then.

Unfortunately, case numbers rose throughout the summer. While UW would allow a very limited number of courses to be held in person in the fall, ChemE ultimately felt the least bad option would be to conduct all courses 100% virtually.

That meant the department would offer two lab courses in autumn quarter — in custom home-science-kit form. Lecturers Chad Curtis and Kyle Caldwell, with support from ChemE facilities manager Kameron Harmon, worked in earnest to design, assemble, package, and distribute everything students would need to re-create labs at home.

How did they minimize experimental setups, provide safe and inexpensive equipment, and swap out hazardous chemicals for kitchen-friendly ingredients? Like most of us during this pandemic, they had to get creative about what you can accomplish at home.

Labs in a kit

The cavernous unit ops lab space in the Benson basement is memorable for many a ChemE, for better or worse. Could any home or apartment really be a substitute? When Chad Curtis distilled the course to its core, he realized it wasn’t such a stretch. He could actually set up very similar experiments to those in Benson; it’s just that the equipment would look different.

This first unit operations course is all about heat transfer and fluid dynamics. To adapt it, Curtis created three different kits — at an average cost of about $35 each — that miniaturize the labs done in person. In the first lab, for example, students measure heat transfer through a brass rod. In Benson, the heat source is steam. In the lab kit, it’s a coffee cup warmer.

For another home lab, students measure how the viscosity of fluids such as olive oil change with temperature. “Everything we used chemical-wise was something you can buy at a grocery store,” he said.

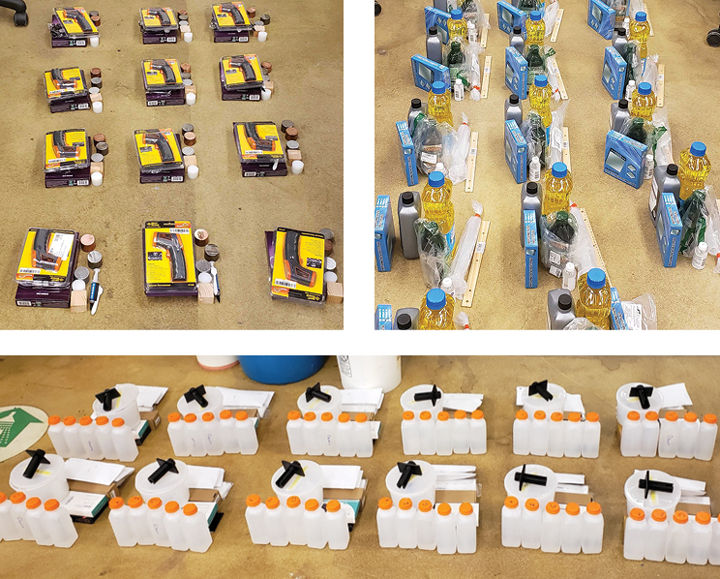

Lab kits, assembled and ready to be packed up and distributed to students. Unit ops kits include an infrared thermometer gun and materials for heat transfer measurements (top left), and fluids such as motor oil and cooking oil (top right.) A surfaces and colloids kit (bottom) includes equipment for drop formation and solution preparation.

Kyle Caldwell, who is teaching the surfaces and colloids lab, had the advantage of professor John Berg’s experience teaching the course. Over the years, Berg has developed upwards of 20 different labs to pick from for each course offering. Caldwell started by going through those tried-and-true options, imagining how each could be adapted to kit form: What could be done on the cheap? Almost everyone has a camera of some sort — could he take advantage of that? Instead of organic solvents, could he use water, cooking oil, and table salt?

“Once I put all those constraints on it, it kind of came together,” he said. After some home experimentation of his own, he assembled four lab kits using components mostly bought from Amazon, all for about $60 per student.

Caldwell leveraged the ubiquity of cell phone cameras and incorporated them into three of the labs. After all, he thought, image analysis is becoming more and more routine in the era of big data, and this was a great opportunity for students to bolster those skills.

One of his lab exercises, for example, involves capturing an image of a drop of soapy water and using image processing software to calculate its surface tension. Another has students photographing test tubes of different salt solutions to determine the stability of suspended clay particles, a concept applicable to wastewater treatment.

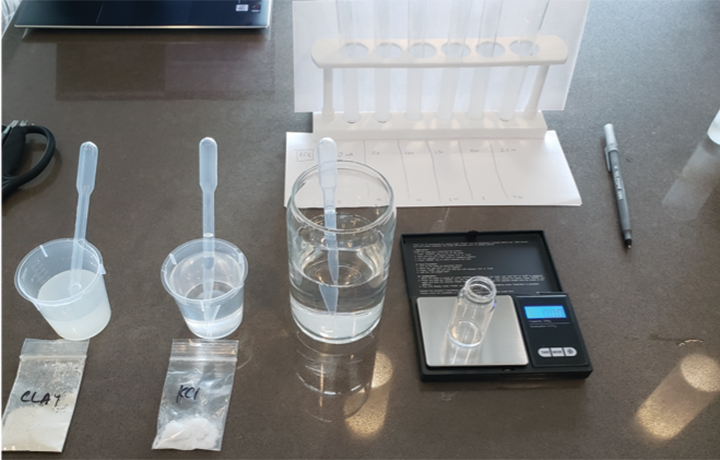

In this surfaces and colloids lab, students use a series of salt solutions to investigate the minimum concentration required to destabilize a dispersed clay particle, mimicking wastewater treatment.

Learning experiences

Lab work inevitably involves some amount of creative problem solving. It is playing out that way with labs at home, sometimes by design and sometimes not. For example, Caldwell intentionally left it to students to find and properly arrange a light source to create good images.

In unit ops, students learned about data quality issues. They discovered their infrared thermometer guns didn’t work well on shiny surfaces, so they sometimes picked up spurious measurements of heat transfer through metal. The workaround: put a piece of tape over the object being measured, or be sure to explain the reason for inconsistencies in the lab report.

The instructors learned, too, from the logistics involved in getting every student up and running. Things like the kits not clearing customs, and some students in Asia, who consequently had to build their own kits, finding that the price of olive oil put them over budget. But both Curtis and Caldwell say such snafus have been few and easy to resolve. (About two-thirds of the students picked up their kits in Benson Hall, and others received theirs in the mail.)

Despite the challenges, the exercise of making labs in kits has expanded the instructors’ thinking about designing future courses. ChemE, as a growing department, is facing more demands on its physical space. Shrinking the footprint of experiments may be a smart strategy for easing some of that crunch. Modular, kit-style labs could be part of in-person courses, but they could use more sophisticated tools (e.g. a heat camera instead of a $20 infrared thermometer) and equipment that’s safe in a lab setting but not necessarily at home (e.g. a Bunsen burner instead of a coffee cup warmer).

Perhaps more importantly, labs at home may just go to show what’s possible with simple, readily available materials. And those low barriers to experimentation could inspire curious engineering students to push themselves further during this time at home.